Empowering Data-Driven Efficiency in Manufacturing

ParetOPS helps your team make smarter decisions, reduce downtime, and boost productivity — all in real time.

ParetOPS is an all-in-one production and maintenance intelligence platform.

It collects real-time data from the shop floor, analyzes trends across machines and shifts, and guides action through live KPIs and smart benchmarks.

Unlike Excel or rigid MES systems, ParetOPS delivers instant visibility, team coordination, and data-backed decisions — without the complexity.

Why ParetOPS?

Real-Time Monitoring

Track key KPIs like OEE, downtime, and output directly from your shop floor.

Smart Reports

Get automatically generated insights to prioritize actions and improve continuously.

Lean Integration

Built with Lean Six Sigma principles — DMAIC-ready, operator-friendly, and scalable.

Feature Highlights

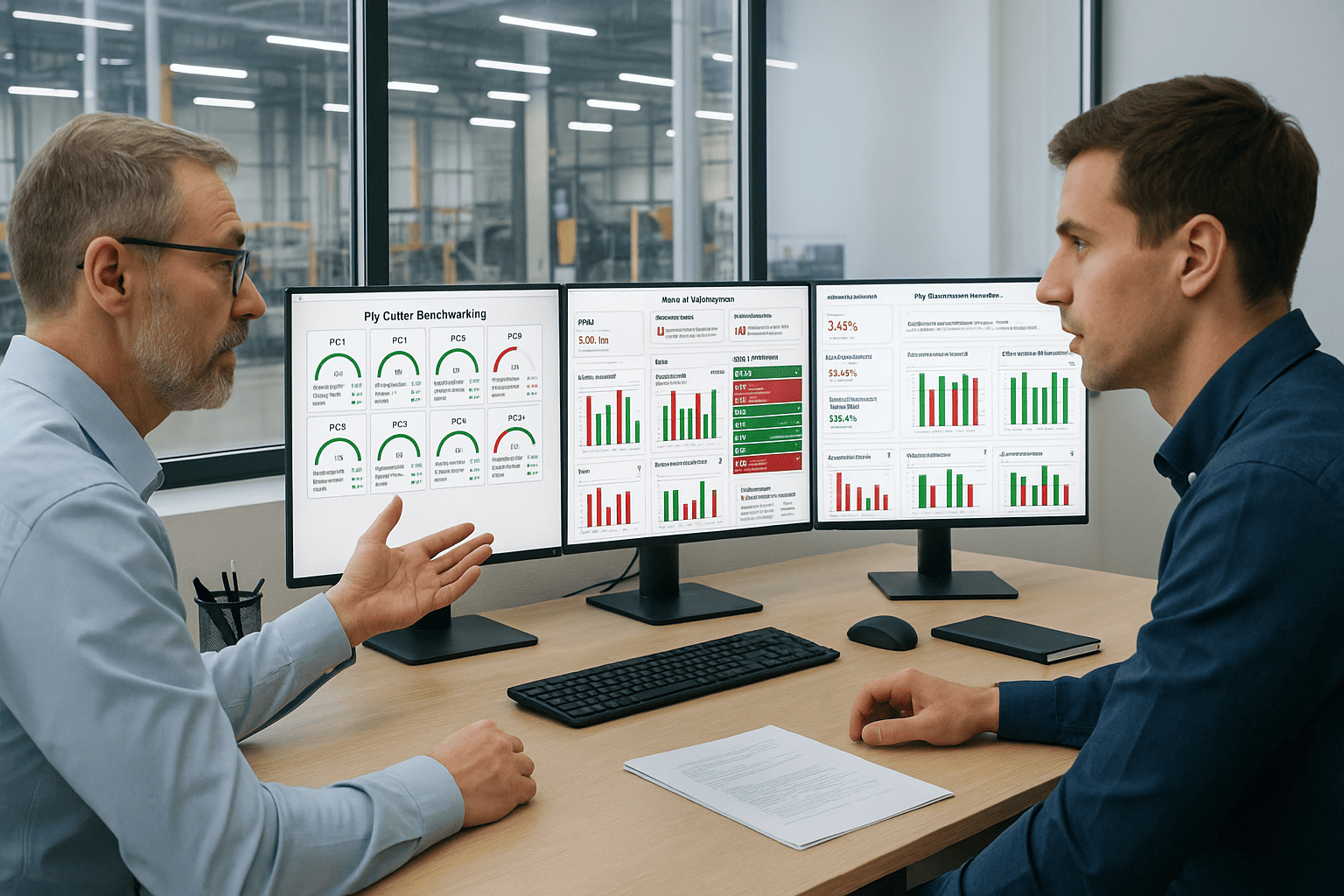

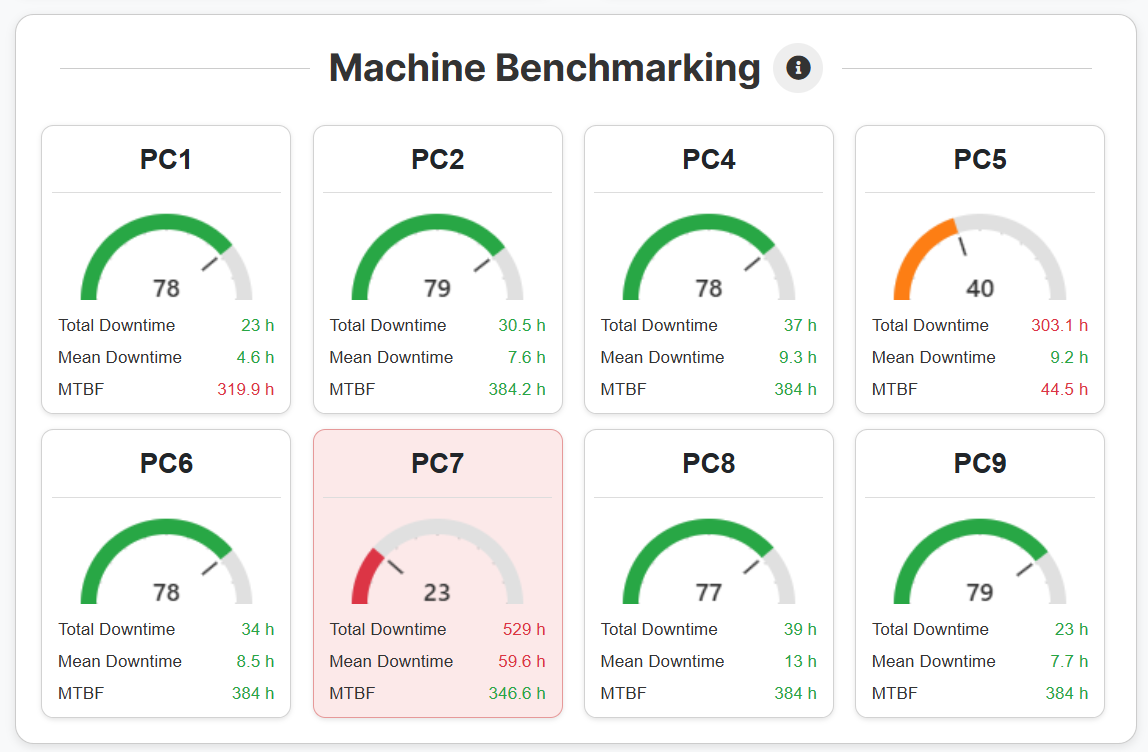

Leader Dashboard

The Leader Dashboard offers long-term visibility into production and maintenance trends. Powered by the ParetOPS algorithm, it highlights emerging patterns and supports data-driven decisions based on real-time updates.

It helps leaders detect issues early, standardize best practices, and compare machine or shift performance. Clear, exportable reports make it easy to justify investments and demonstrate ROI.

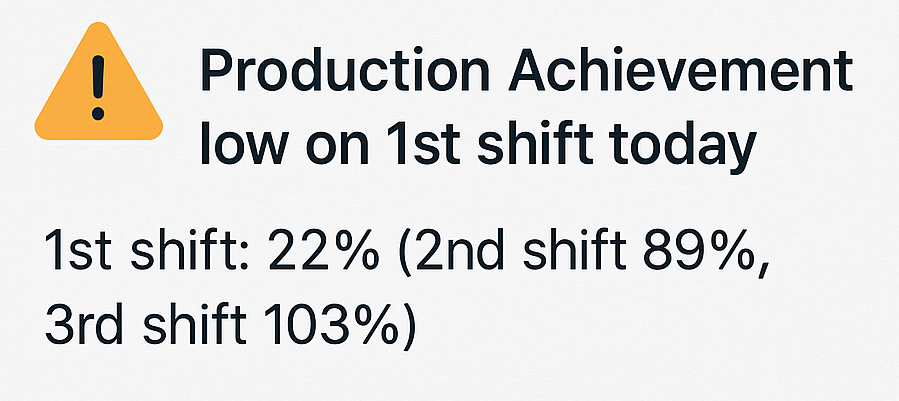

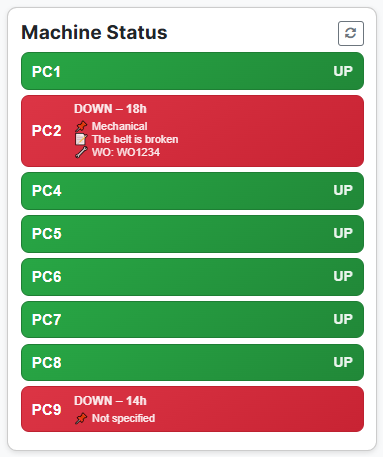

Live Alerts & Accountability

Designed for immediate impact, the Daily Dashboard alerts leaders in real time when support is needed or deviations occur.

It empowers instant adjustments to targets, priorities, and resource allocation—enhancing accountability and keeping operations fluid.

From urgency to mastery—ParetOPS ensures controlled flow.

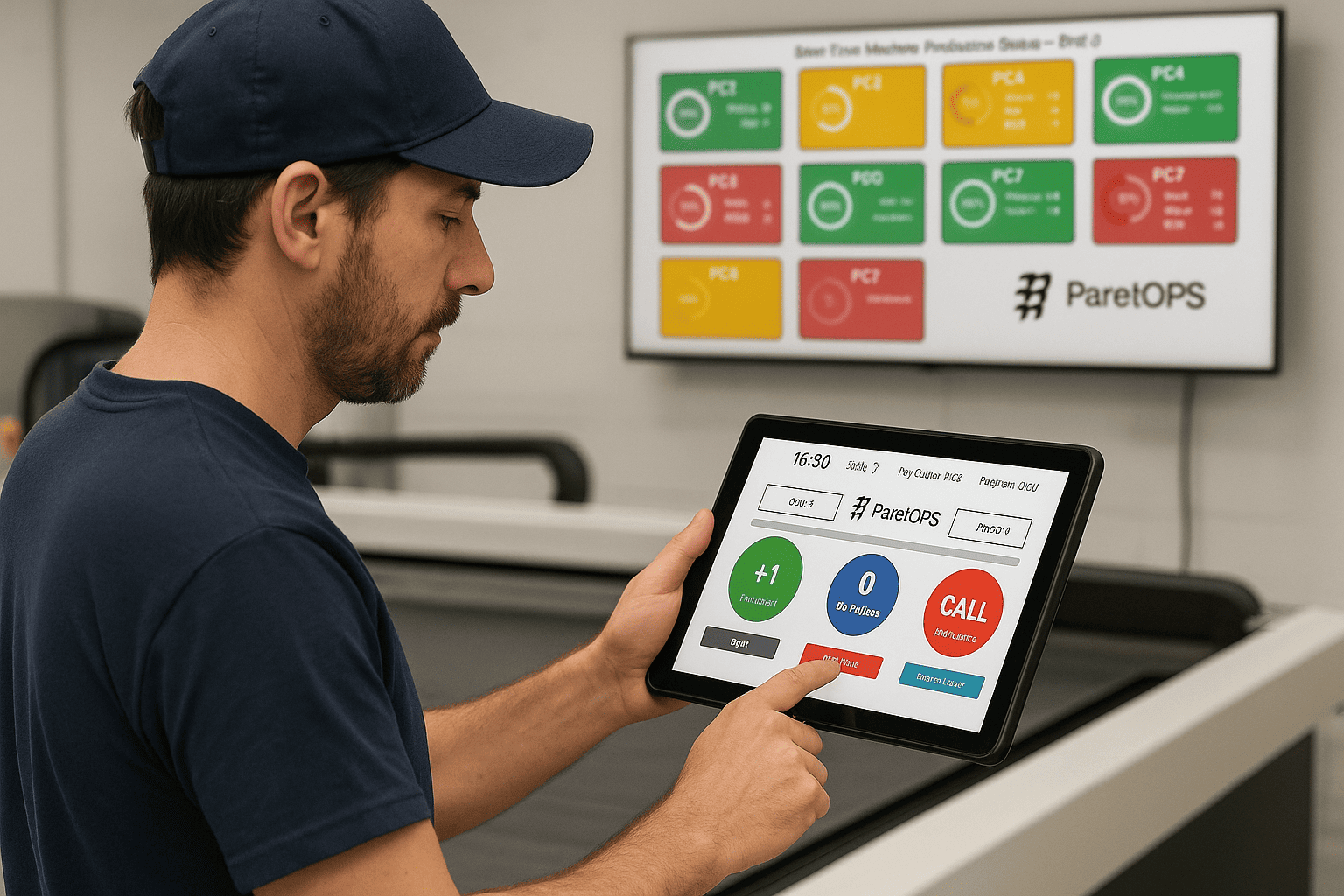

Tablet-Based Input

Operators log production or maintenance events in seconds through a simple, intuitive interface—no training needed.

The system runs on any standard tablet and requires no complex setup, making deployment effortless and impactful.

Every input is time-stamped and can linked to the operator, ensuring full traceability and reinforcing accountability across the shop floor.

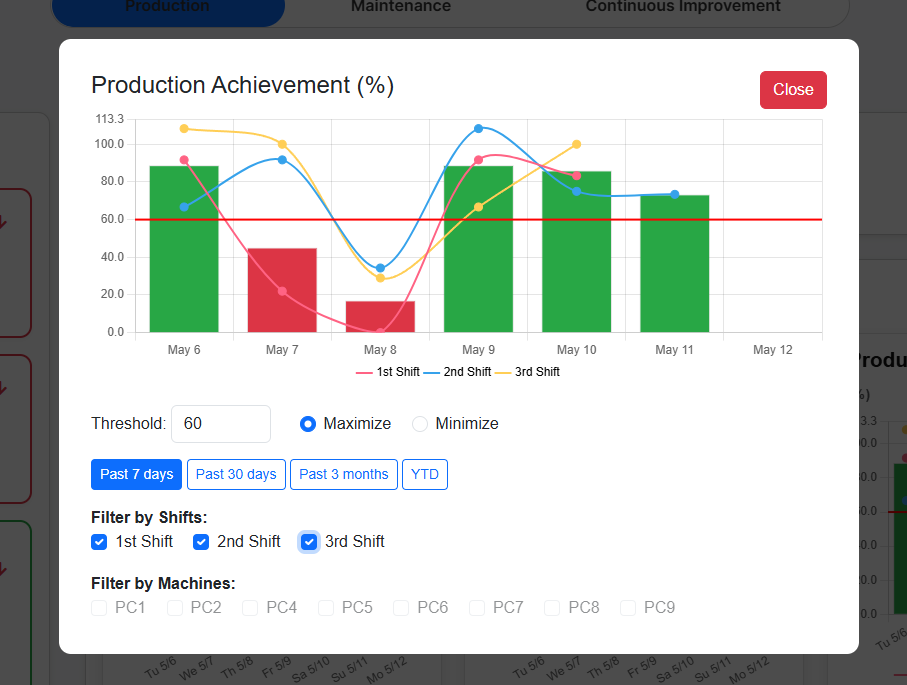

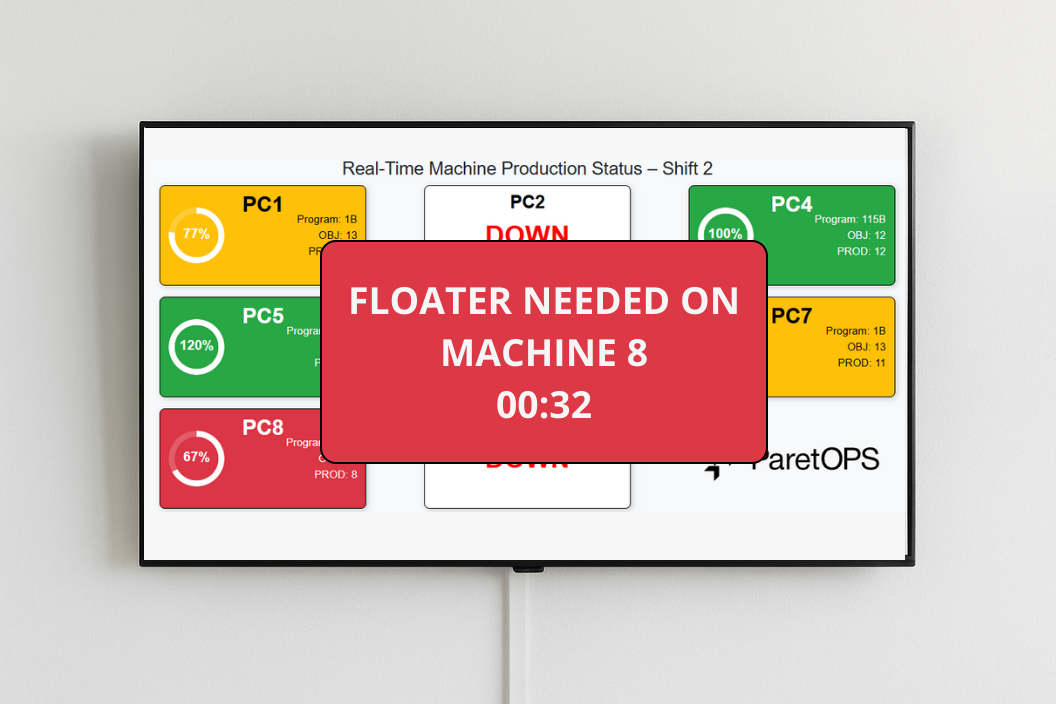

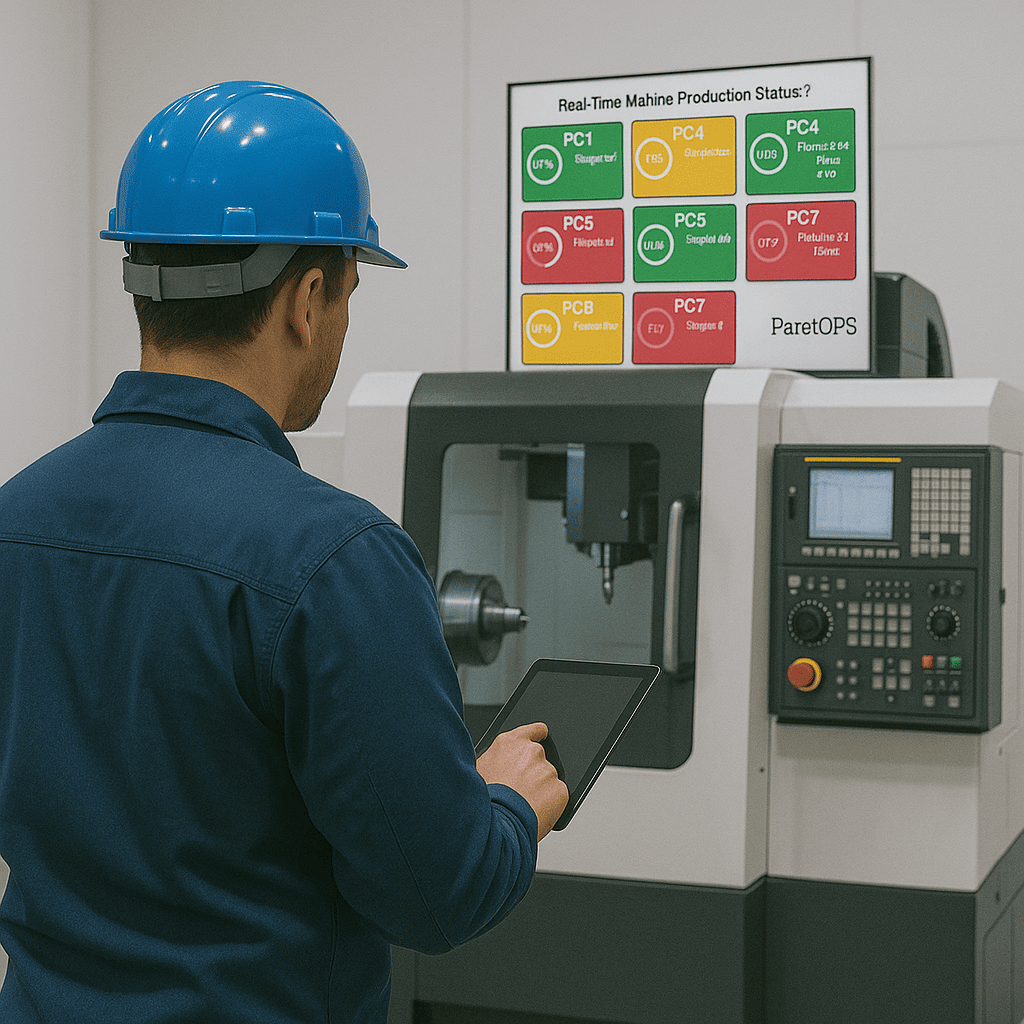

Real-Time Visuals

Large-screen TVs broadcast live production metrics across the shop floor, helping teams stay focused and aligned.

Operators instantly see goals, progress, and alerts—enhancing reactivity and driving collective performance.

This shared visibility fosters a stronger team dynamic, where everyone understands priorities and contributes to the same production targets.

Plug-ins Available

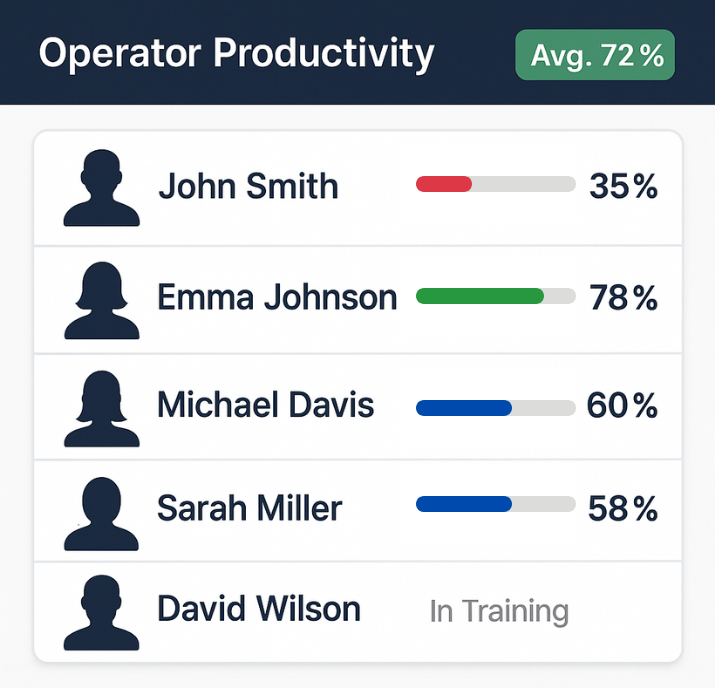

Operator Productivity

Measure individual effort, identify slowdowns, and motivate your team with real-time scoring logic.

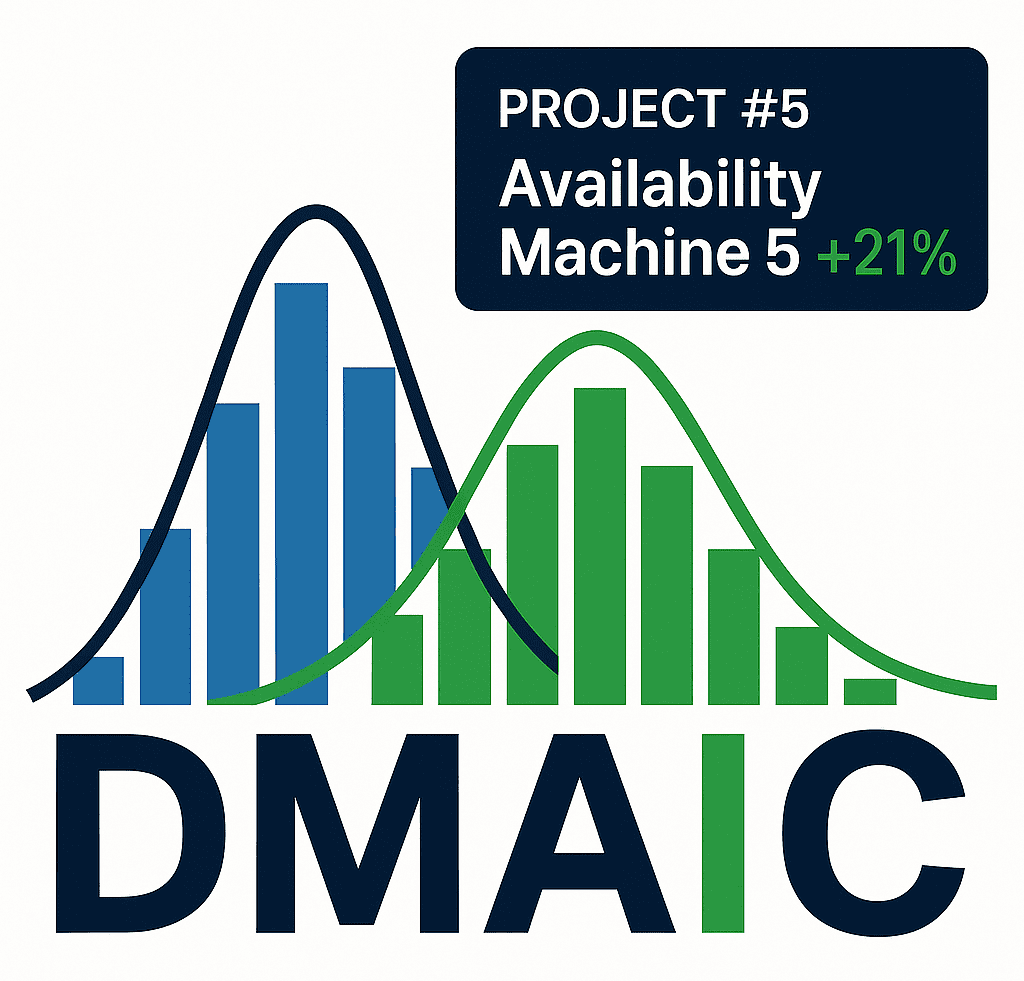

Continuous Improvement – Quick Sigma

Deploy Lean & DMAIC projects step-by-step using an interactive workspace. Measure impact through real KPIs and structured follow-up.

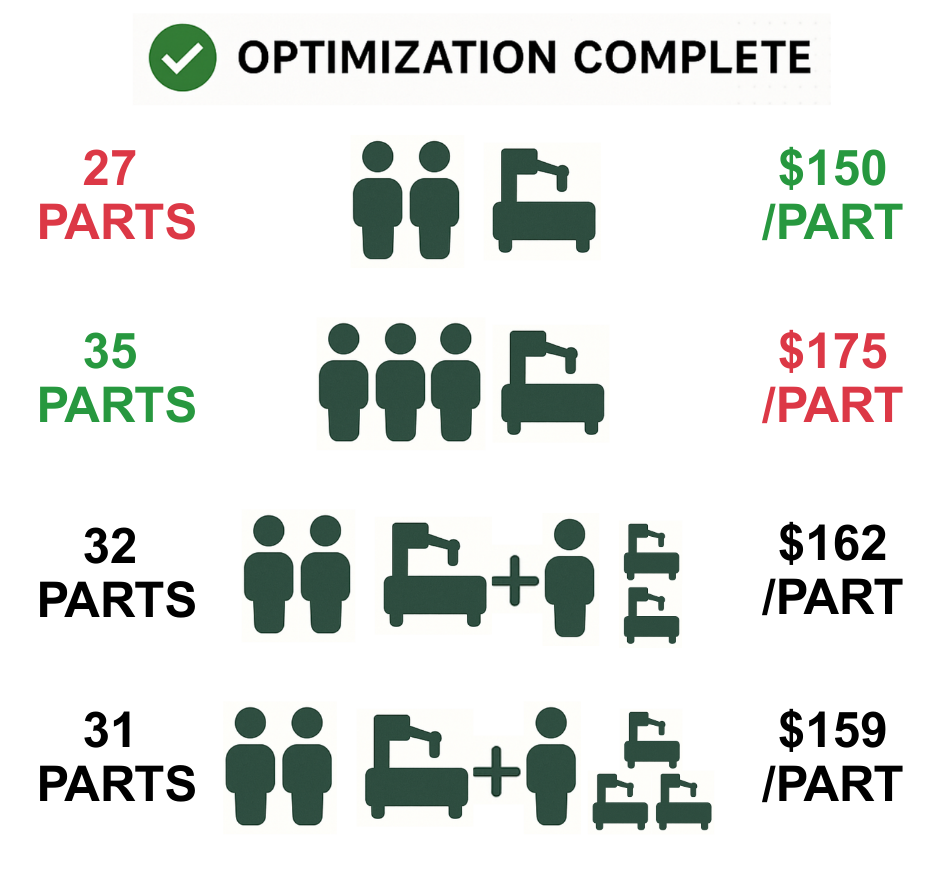

Workforce Optimizer

Optimize workforce per machine to find the best balance between output and unit cost, based on real performance data.

Custom Features on Request

If a needed feature is missing, the ParetOPS team can evaluate and develop it. The platform is modular and adapts to your needs.

Built for Performance-Driven Teams

- ● Trusted by top aerospace manufacturers to increase availability, utilization, and efficiency across their production lines.

- ● Improved production capacity by 25%, avoiding costly investments in new machines.

- ● Aligned daily execution with long-term performance goals through live dashboards and instant alerts.